Historic Bowens Mills

We are sad to announce that we can no longer have “It’s Cider Time” festivals at Historic Bowen Mills.

Unfortunately the “State of Michigan” has decided that our cider making days have come to an end.

We have been celebrating the fall season at Bowens Mills for over 40 years and we have very much enjoyed sharing that with all of you.

Thank you so much for all of your support in helping us to continue to preserve the history of days gone by at Bowens Mills through the years.

We would also like to thank the many people that have volunteered their time and been so faithful at supporting us and making our events successful.

Please keep us in your thoughts and prayers as we make this difficult adjustment.

Owen and Carleen Sabin

Video can’t be displayed

This video is not available.

Please Enjoy Reading the History

Hot apple dumplins', cider pressing on an antique press & cornmeal that is ground on the original equipment used in 1864, along with horse drawn rides, live music, an antique tractor display, a farm animal petting area and much more. As the celebration of the harvest season and a place in time, begins at Bowens Mills with "October Cider Sundays" old time family fun.

More than 40 years ago the late Neal Cook and his wife Marion with the help of their children, grand children, family and friends all joined together to resurrect a 19th- century water powered cider press located in an old mill near Middleville, Michigan. With great anticipation they watched as the first cider came oozing from the cider blankets and the huge press chugged along. There were big smiles and giggles of excitement as they sipped the first cider that day, and every fall from that year forward the fun continued. Today the second generation of millers, Owen & Carleen Sabin, take their turn offering, the sights and sips of cidering through the fall harvest festival time at the old mill.

The gigantic cider press, (which was not new at the time) was moved to the mill property in 1902. The old timers tell how it was in the old days, when horses and wagons loaded with their apples were lined all the way back into town, waiting their turn at the press. Today folks come from miles around to see the past live again as bushel and bushels of apples are made into gallons and gallons of cider on the old press.

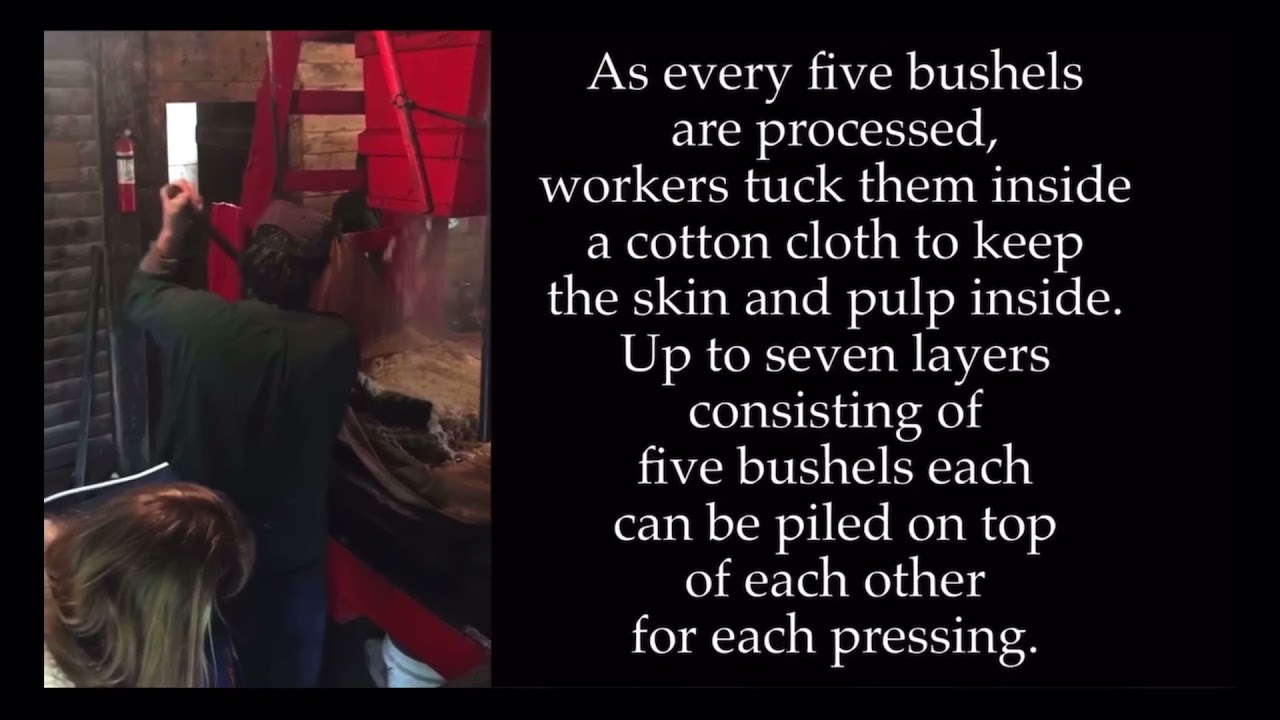

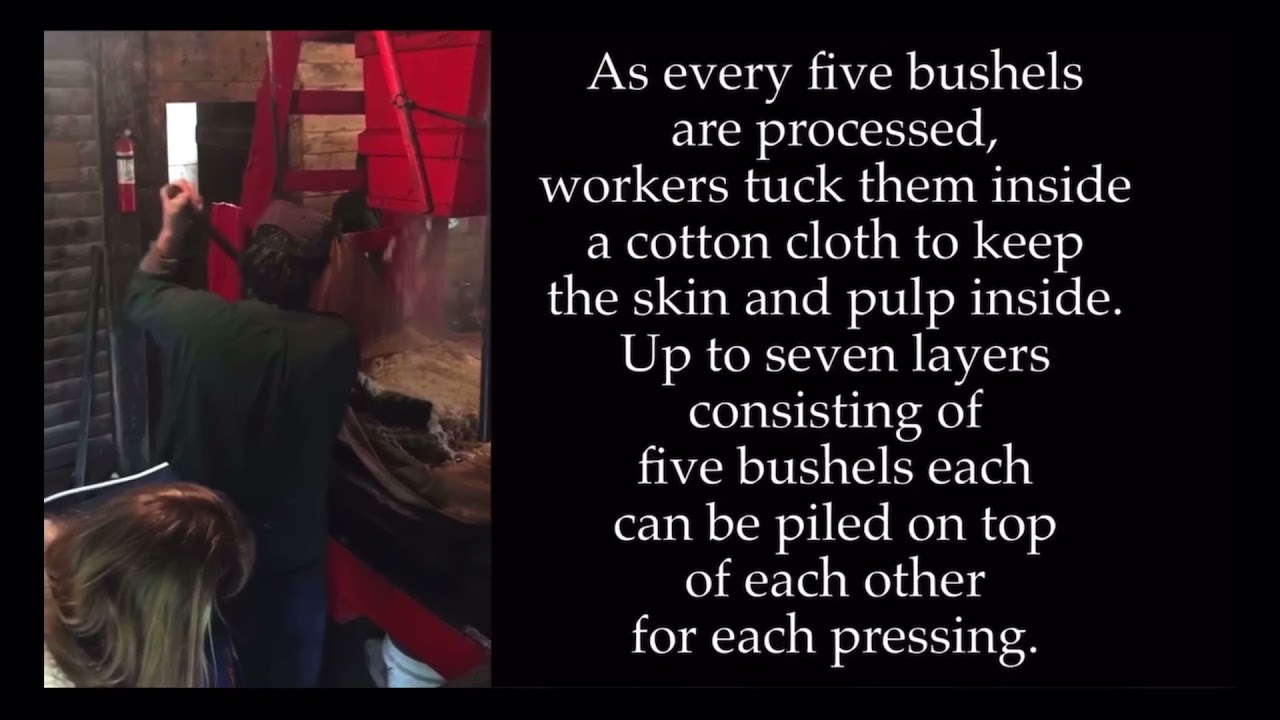

A complex mixture of gears, pulleys, and belts rumble, clank and rattle overhead as a water-powered conveyor belt marches apples toward a giant, knife-filled hopper; the fruit is chopped into a huge apple salad. As every five bushels are processed, workers tuck them inside a cotton cloth to keep the skin and pulp inside. Up to seven layers consisting of five bushels each can be piled on top of each other for each pressing. After the layers are stacked up, the miller cranks a gear to place the apple pulp underneath a 50-ton press. Then it is a simple matter of waiting for the water pumps to build up enough pressure inside the cylindrical press to squeeze every last drop of sweet apple cider.

The 12-foot-tall press takes half an hour to press 100 gallons of cider from 35 bushels of apples. It is powered by the water from the mill pond, which originates at Barlow Lake, then passes through the mill and continues to Payne Creek and then to Payne Lake and eventually emptying into Gun Lake. The old press was moved into the mill used over 100 years ago and is still continues to press today for demonstration.

A tasty cider requires a mixture of apples. The best mixture would be some tart apples with some sweet apples and some acidy apples. Such a mixture could be Mackintosh, some Spy, and some Red Delicious. Some people even add pears to the press to give the cider a bit of a bite.

The process is the same as hundreds of years ago, but the names of the apples have changed from Russet, Pippin, and Maiden's Blush to Jonathan, Macintosh, Rome and Spy.

The process for creating sweet apple cider remains virtually unchanged from the time that William Blaxton, a colonial settler, planted the first apple orchard on the slope of Boston's Beacon Hill. The ingredients of real apple cider are simple: apples. No preservatives, no added colors, sugars or chemicals - just apples, apples and more apples. Since colonial times, when John Adams drank a tankard of cider every morning before breakfast, cider pressing has been a familiar sight at the harvest festival.

The gigantic cider press, (which was not new at the time) was moved to the mill property in 1902. The old timers tell how it was in the old days, when horses and wagons loaded with their apples were lined all the way back into town, waiting their turn at the press. Today folks come from miles around to see the past live again as bushel and bushels of apples are made into gallons and gallons of cider on the old press.

A complex mixture of gears, pulleys, and belts rumble, clank and rattle overhead as a water-powered conveyor belt marches apples toward a giant, knife-filled hopper; the fruit is chopped into a huge apple salad. As every five bushels are processed, workers tuck them inside a cotton cloth to keep the skin and pulp inside. Up to seven layers consisting of five bushels each can be piled on top of each other for each pressing. After the layers are stacked up, the miller cranks a gear to place the apple pulp underneath a 50-ton press. Then it is a simple matter of waiting for the water pumps to build up enough pressure inside the cylindrical press to squeeze every last drop of sweet apple cider.

The 12-foot-tall press takes half an hour to press 100 gallons of cider from 35 bushels of apples. It is powered by the water from the mill pond, which originates at Barlow Lake, then passes through the mill and continues to Payne Creek and then to Payne Lake and eventually emptying into Gun Lake. The old press was moved into the mill used over 100 years ago and is still continues to press today for demonstration.

A tasty cider requires a mixture of apples. The best mixture would be some tart apples with some sweet apples and some acidy apples. Such a mixture could be Mackintosh, some Spy, and some Red Delicious. Some people even add pears to the press to give the cider a bit of a bite.

The process is the same as hundreds of years ago, but the names of the apples have changed from Russet, Pippin, and Maiden's Blush to Jonathan, Macintosh, Rome and Spy.

The process for creating sweet apple cider remains virtually unchanged from the time that William Blaxton, a colonial settler, planted the first apple orchard on the slope of Boston's Beacon Hill. The ingredients of real apple cider are simple: apples. No preservatives, no added colors, sugars or chemicals - just apples, apples and more apples. Since colonial times, when John Adams drank a tankard of cider every morning before breakfast, cider pressing has been a familiar sight at the harvest festival.

The Past Lives Again at Bowens Mills. Please feel free to email us at BowensMills@gmail.com

Video can’t be displayed

This video is not available.

Historic Bowens Mills

We are sad to announce that we can no longer have “It’s Cider Time” festivals at Historic Bowen Mills.

Unfortunately the “State of Michigan” has decided that our cider making days have come to an end.

We have been celebrating the fall season at Bowens Mills for over 40 years and we have very much enjoyed sharing that with all of you.

Thank you so much for all of your support in helping us to continue to preserve the history of days gone by at Bowens Mills through the years.

We would also like to thank the many people that have volunteered their time and been so faithful at supporting us and making our events successful.

Please keep us in your thoughts and prayers as we make this difficult adjustment.

Owen and Carleen Sabin

Video can’t be displayed

This video is not available.

Please Enjoy Reading the History

Hot apple dumplins', cider pressing on an antique press & cornmeal that is ground on the original equipment used in 1864, along with horse drawn rides, live music, an antique tractor display, a farm animal petting area and much more. As the celebration of the harvest season and a place in time, begins at Bowens Mills with "October Cider Sundays" old time family fun.

More than 40 years ago the late Neal Cook and his wife Marion with the help of their children, grand children, family and friends all joined together to resurrect a 19th- century water powered cider press located in an old mill near Middleville, Michigan. With great anticipation they watched as the first cider came oozing from the cider blankets and the huge press chugged along. There were big smiles and giggles of excitement as they sipped the first cider that day, and every fall from that year forward the fun continued. Today the second generation of millers, Owen & Carleen Sabin, take their turn offering, the sights and sips of cidering through the fall harvest festival time at the old mill.

The gigantic cider press, (which was not new at the time) was moved to the mill property in 1902. The old timers tell how it was in the old days, when horses and wagons loaded with their apples were lined all the way back into town, waiting their turn at the press. Today folks come from miles around to see the past live again as bushel and bushels of apples are made into gallons and gallons of cider on the old press.

A complex mixture of gears, pulleys, and belts rumble, clank and rattle overhead as a water-powered conveyor belt marches apples toward a giant, knife-filled hopper; the fruit is chopped into a huge apple salad. As every five bushels are processed, workers tuck them inside a cotton cloth to keep the skin and pulp inside. Up to seven layers consisting of five bushels each can be piled on top of each other for each pressing. After the layers are stacked up, the miller cranks a gear to place the apple pulp underneath a 50-ton press. Then it is a simple matter of waiting for the water pumps to build up enough pressure inside the cylindrical press to squeeze every last drop of sweet apple cider.

The 12-foot-tall press takes half an hour to press 100 gallons of cider from 35 bushels of apples. It is powered by the water from the mill pond, which originates at Barlow Lake, then passes through the mill and continues to Payne Creek and then to Payne Lake and eventually emptying into Gun Lake. The old press was moved into the mill used over 100 years ago and is still continues to press today for demonstration.

A tasty cider requires a mixture of apples. The best mixture would be some tart apples with some sweet apples and some acidy apples. Such a mixture could be Mackintosh, some Spy, and some Red Delicious. Some people even add pears to the press to give the cider a bit of a bite.

The process is the same as hundreds of years ago, but the names of the apples have changed from Russet, Pippin, and Maiden's Blush to Jonathan, Macintosh, Rome and Spy.

The process for creating sweet apple cider remains virtually unchanged from the time that William Blaxton, a colonial settler, planted the first apple orchard on the slope of Boston's Beacon Hill. The ingredients of real apple cider are simple: apples. No preservatives, no added colors, sugars or chemicals - just apples, apples and more apples. Since colonial times, when John Adams drank a tankard of cider every morning before breakfast, cider pressing has been a familiar sight at the harvest festival.

The gigantic cider press, (which was not new at the time) was moved to the mill property in 1902. The old timers tell how it was in the old days, when horses and wagons loaded with their apples were lined all the way back into town, waiting their turn at the press. Today folks come from miles around to see the past live again as bushel and bushels of apples are made into gallons and gallons of cider on the old press.

A complex mixture of gears, pulleys, and belts rumble, clank and rattle overhead as a water-powered conveyor belt marches apples toward a giant, knife-filled hopper; the fruit is chopped into a huge apple salad. As every five bushels are processed, workers tuck them inside a cotton cloth to keep the skin and pulp inside. Up to seven layers consisting of five bushels each can be piled on top of each other for each pressing. After the layers are stacked up, the miller cranks a gear to place the apple pulp underneath a 50-ton press. Then it is a simple matter of waiting for the water pumps to build up enough pressure inside the cylindrical press to squeeze every last drop of sweet apple cider.

The 12-foot-tall press takes half an hour to press 100 gallons of cider from 35 bushels of apples. It is powered by the water from the mill pond, which originates at Barlow Lake, then passes through the mill and continues to Payne Creek and then to Payne Lake and eventually emptying into Gun Lake. The old press was moved into the mill used over 100 years ago and is still continues to press today for demonstration.

A tasty cider requires a mixture of apples. The best mixture would be some tart apples with some sweet apples and some acidy apples. Such a mixture could be Mackintosh, some Spy, and some Red Delicious. Some people even add pears to the press to give the cider a bit of a bite.

The process is the same as hundreds of years ago, but the names of the apples have changed from Russet, Pippin, and Maiden's Blush to Jonathan, Macintosh, Rome and Spy.

The process for creating sweet apple cider remains virtually unchanged from the time that William Blaxton, a colonial settler, planted the first apple orchard on the slope of Boston's Beacon Hill. The ingredients of real apple cider are simple: apples. No preservatives, no added colors, sugars or chemicals - just apples, apples and more apples. Since colonial times, when John Adams drank a tankard of cider every morning before breakfast, cider pressing has been a familiar sight at the harvest festival.

The Past Lives Again at Bowens Mills. Please feel free to email us at BowensMills@gmail.com

Video can’t be displayed

This video is not available.